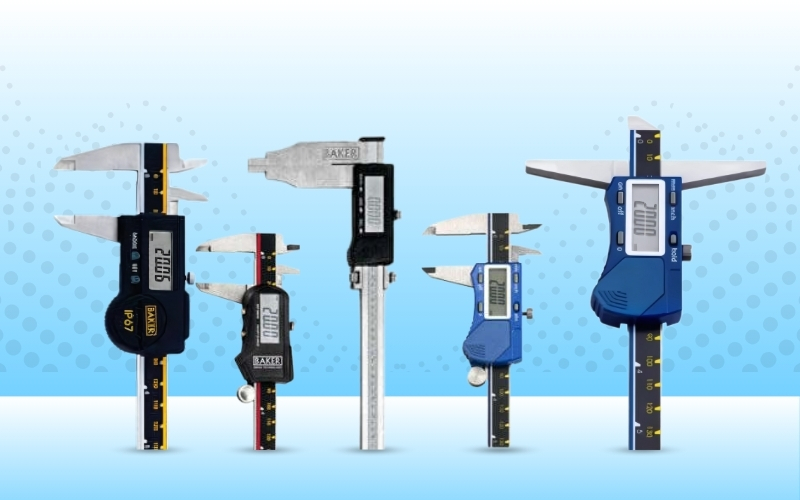

Vernier Calipers are a cornerstone of precision measurement, widely used across industries that demand accuracy and reliability. These versatile instruments enable users to measure internal and external dimensions, depths, and more. In this blog, we will explore the Uses and Applications of Vernier Calipers, shedding light on why they remain essential in engineering, manufacturing, and beyond.

What are Vernier Calipers?

A Vernier Caliper is a precision measuring tool equipped with a sliding scale (the Vernier scale) that enhances measurement accuracy. They are primarily used to measure internal and external dimensions, diameters, and depths with incredible precision, typically to the nearest 0.02mm or 0.001 inches.

Top Uses of Vernier Calipers

1. Measuring External Dimensions

Vernier Calipers are commonly used to Measure the External Dimensions of objects, such as the diameter of cylindrical components or the width of machine parts. The jaws of the caliper firmly hold the object, providing precise measurements.

2. Measuring Internal Dimensions

The Smaller, Upper Jaws of Vernier Calipers are designed to measure internal dimensions, such as the diameter of holes or the width of slots. This feature makes them invaluable in applications where internal precision is critical.

3. Depth Measurements

The Depth Rod of a Vernier Caliper allows users to measure the depth of holes, grooves, or recesses. This capability is particularly useful in applications like Machining and Quality Control.

4. Accurate Step Measurements

Vernier Calipers can also measure steps on workpieces, ensuring the levels of stepped surfaces meet exact specifications.

5. Thickness and Diameter Checks

Vernier Calipers are frequently employed to verify the thickness of materials and diameters of wires, pipes, and other round objects.

Applications of Vernier Calipers across Industries

1. Engineering and Manufacturing

In these Industries, Vernier Calipers ensure that machine components, tools, and assembly parts meet precise dimensions. They are indispensable for achieving tight tolerances in production.

2. Automotive Industry

From measuring Engine Parts to verifying the dimensions of gears, Vernier Calipers are critical in the automotive sector. They help ensure parts fit and function perfectly, enhancing vehicle performance.

3. Medical Equipment Production

The precision of Vernier Calipers is vital in creating medical devices and instruments, where even slight inaccuracies can affect functionality.

4. Aerospace Industry

The Aerospace Industry relies heavily on precision tools like Vernier Calipers to measure components that demand extreme accuracy, such as turbine blades and fuselage parts.

5. Academic and Research Laboratories

In Educational and Research Settings, Vernier Calipers are often used to teach principles of measurement and conduct experiments that require precise readings.

Advantages of Using Vernier Calipers

- High Precision: The Vernier scale allows for measurements with remarkable accuracy, making these tools ideal for critical tasks.

- Versatility: Suitable for measuring various dimensions, including length, diameter, depth, and step heights.

- Durability: High-quality Vernier calipers, often made of stainless steel, withstand frequent use in demanding environments.

- Ease of Use: Clear markings and a simple sliding mechanism make them user-friendly for professionals and beginners alike.

How to use a Vernier Caliper for Accurate Measurements

- Zero the Caliper: Ensure the caliper reads “0” when fully closed to avoid errors.

- Position the Object: Place the object between the caliper’s jaws or against the depth rod.

- Read the Measurement: Use the main scale and the Vernier scale to determine the exact reading.

- Record Results: Note the measurement for reference or further processing.

Choosing the Right Vernier Caliper

When selecting a Vernier Caliper, consider the following factors:

- Measurement Range: Choose a caliper that covers the size range of your typical measurements.

- Material and Build Quality: Opt for stainless steel or other durable materials for longevity.

- Metric vs. Imperial Units: Ensure the caliper matches the measurement system you frequently use.

- Digital vs. Manual: While traditional calipers are highly reliable, digital calipers offer ease of reading and additional features like data output.

Conclusion

Vernier Calipers are more than just tools; they are a gateway to precision. Their versatility and reliability make them a staple in industries ranging from manufacturing to medicine. Whether you’re a professional engineer, a student, or a hobbyist, Vernier calipers ensure that your measurements are accurate and consistent.

By incorporating Vernier Calipers into your toolkit, you gain a trusted companion for tasks requiring meticulous attention to detail. Embrace the power of precision and elevate your projects to new heights with this indispensable instrument.