In precision manufacturing, even the smallest deviation can lead to assembly failures, leakage, or premature wear. This is where Thread Gauges become essential for ensuring dimensional accuracy and consistent performance across production lines.

This guide explains what thread gauges are, why they matter, the different types available, their applications, and how to select the right solution for industrial quality control.

What Are Thread Gauges?

Thread Gauges are inspection tools used to verify the accuracy of screw threads on components such as bolts, nuts, and internally threaded holes.

Instead of measuring dimensions numerically, GO / NO-GO Thread Gauges confirm whether a thread falls within specified tolerance limits.

They help manufacturers ensure:

- Proper fit between mating parts

- Compliance with international standards

- Consistency in mass production using precision thread gauges

Why Thread Gauges Matter in Precision Measurement

Threaded components must be interchangeable and reliable. Even minor thread errors can cause cross-threading, leakage, or assembly rejection.

Using thread gauges for quality control helps manufacturers:

- Detect manufacturing defects early

- Prevent costly rework or scrap

- Ensure smooth assembly on the shop floor

In high-volume manufacturing, industrial thread gauges remain the fastest and most reliable inspection method.

Types of Thread Gauges

Different inspection needs require different types of thread inspection gauges.

- Thread Plug Gauges

Used for inspecting internal threads such as tapped holes and nuts.

- GO and NO-GO configurations

- Widely used in automotive and machining industries

(No link here – reserve for Thread Plug Gauge product page later)

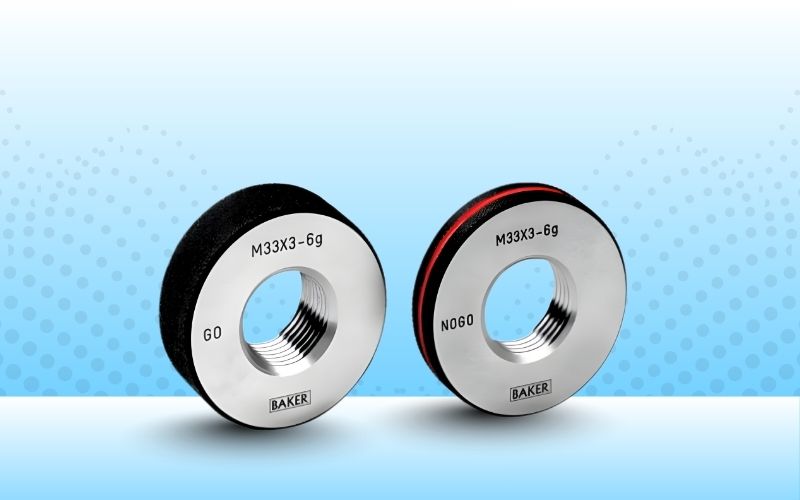

- Thread Ring Gauges

Designed for inspecting external threads like bolts and screws.

- Thread Snap Gauges

Used for quick inspection of external threads in mass production environments.

- Taper Thread Gauges

Used for tapered threads such as BSPT and NPT in fluid-handling systems.

Applications of Thread Gauges Across Industries

Thread Gauges for Manufacturing play a critical role in multiple industries:

- Automotive components and fasteners

- Aerospace precision assemblies

- Oil & gas pipe fittings

- Machining and tool rooms

- Electrical and electronic enclosures

Wherever threaded parts are critical, high-accuracy thread gauges ensure reliable performance.

How to Choose the Right Thread Gauge

Selecting the right thread gauges for internal and external threads ensures inspection accuracy and long service life.

Key factors include:

- Thread type and profile

- Internal or external application

- Class of fit and tolerance

- Compliance with ISO, ANSI, BS, or DIN standards

Thread Gauges and Quality Control

In structured inspection systems, GO / NO-GO Thread Gauges support repeatability and audit compliance.

They reduce dependency on complex measuring equipment while improving confidence in final assemblies.

Conclusion

Thread gauges may appear simple, but their impact on product quality is significant. By investing in reliable thread gauges from a trusted supplier, manufacturers can reduce rejection rates and maintain consistent quality.

For businesses looking to buy thread gauges in India, choosing precision-engineered solutions ensures long-term value and performance.