In Modern Machinery and Industrial Applications, the smooth and efficient operation of Hydraulic and Pneumatic Systems is crucial for success. These systems power everything from construction equipment to Manufacturing Machinery. One component that plays a pivotal role in ensuring these systems function at their best is the Setting Ring. Though small in size, Setting Rings are essential for the accurate alignment, sealing, and overall efficiency of Hydraulic and Pneumatic Systems. In this blog, we will explore the role of Setting Rings in these systems, their uses, and why they are key to achieving optimal performance.

What is a Setting Ring?

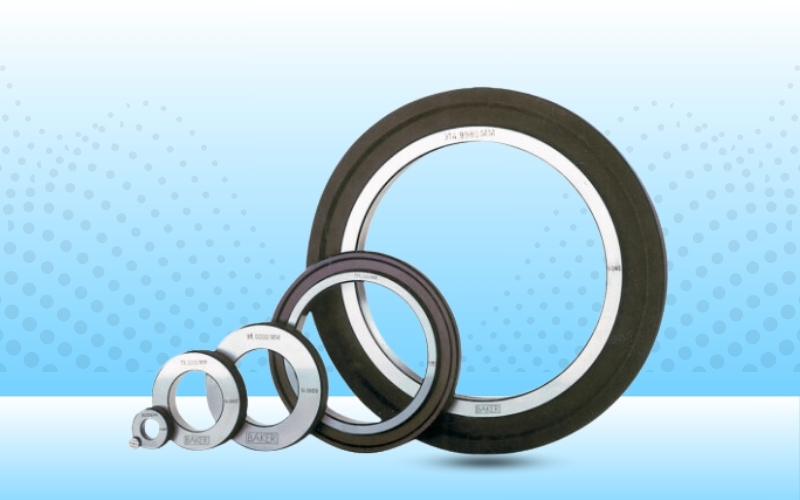

A Setting Ring is a specialized mechanical component designed to maintain the precise alignment of parts within a system. These rings are often made from durable materials such as Stainless Steel or Alloy Steel, depending on the application’s demands. Setting rings are used in various industries to ensure that parts within hydraulic or pneumatic systems are positioned correctly and sealed effectively, preventing leaks, wear, or failure.

In Hydraulic Systems, Setting Rings are typically used to regulate the movement of pistons, control fluid flow, and prevent excessive pressure. In pneumatic systems, these rings are used to secure air compressors, valves, and cylinders. Their primary role is to ensure that every part is correctly positioned for optimal functionality, thereby extending the life of the entire system.

Importance of Setting Rings in Hydraulic Systems

Hydraulic Systems, which rely on fluid power to operate machinery and equipment, require precise alignment of components to function effectively. Setting Rings are essential in maintaining the right amount of compression and sealing within these systems.

- Preventing Leaks and Maintaining Pressure

In hydraulic systems, pressure control is critical for smooth operations. Setting rings are used to prevent leaks by ensuring that seals are tight and that hydraulic fluid flows as intended. A faulty or misaligned setting ring can lead to loss of pressure, causing inefficient operation or complete system failure. By maintaining proper sealing, setting rings ensures that hydraulic components like pumps, valves, and actuators work efficiently. - Reducing Wear and Tear

Hydraulic systems are often exposed to high pressure and temperature variations, which can cause wear and tear over time. Setting rings helps to reduce this wear by maintaining precise alignment and ensuring that parts do not experience undue friction or misalignment. This not only helps maintain the integrity of the system but also increases the longevity of hydraulic components. - Optimizing Fluid Flow

Setting rings are also used to optimize fluid flow within the system. In hydraulic cylinders, for example, these rings prevent internal leakage while ensuring that the hydraulic fluid flows smoothly through the system. This results in a more efficient system and better control over the machinery being powered by the hydraulics.

Role of Setting Rings in Pneumatic Systems

Pneumatic Systems, which operate using compressed air, also rely heavily on setting rings to ensure smooth and efficient operation. In these systems, the role of setting rings is just as critical as in hydraulics.

- Ensuring Proper Alignment of Pneumatic Components

Pneumatic Systems often consist of complex networks of compressors, valves, cylinders, and regulators. Setting rings helps keep these components properly aligned, ensuring that air flows freely and pressure is maintained. Without proper alignment, the efficiency of the system could be compromised, leading to unnecessary energy consumption or even damage to the components. - Sealing and Pressure Control

Just like in Hydraulic Systems, Sealing, and Pressure Control are essential in pneumatic systems. Setting Rings are used to form tight seals around critical parts, preventing air leaks and ensuring that the compressed air reaches its destination with consistent pressure. This is crucial for machinery that relies on precise air control, such as in robotics, manufacturing equipment, and automated systems. - Reducing Energy Loss

Energy loss in pneumatic systems can occur if air leaks or if the system is misaligned. Setting Rings helps minimize energy loss by keeping the system sealed and components aligned. This leads to improved system efficiency and reduced energy consumption, which is beneficial for both cost savings and environmental sustainability.

Applications of Setting Rings in Hydraulic and Pneumatic Systems

Setting Rings are used in a wide range of applications across multiple industries. Here are some examples where setting rings play a key role:

- Construction and Heavy Equipment

Hydraulic Systems in construction equipment, such as excavators and cranes, rely on setting rings to ensure efficient fluid flow and pressure control. Without these rings, components like hydraulic cylinders would fail to function properly, leading to equipment downtime. - Automotive Industry

In the Automotive Industry, Pneumatic Systems are used in assembly lines, air brakes, and suspension systems. Setting rings ensures the alignment and sealing of pneumatic valves and cylinders, helping to maintain system performance and safety. - Aerospace

Setting Rings is essential in the Aerospace Industry, where both hydraulic and pneumatic systems are critical. These rings help ensure that components like actuators, landing gear, and control systems operate smoothly under extreme conditions, including high pressures and fluctuating temperatures. - Manufacturing and Automation

In Manufacturing Environments, where Hydraulic and Pneumatic Systems Drive Machinery, Setting Rings helps ensure consistent operation and prevent system failures. They are used in machines like CNC Machines, Pneumatic Press Brakes, and Automated Assembly Systems.

How to Choose the Right Setting Ring

When choosing a Setting Ring for your hydraulic or pneumatic system, several factors need to be considered. The material of the Setting Ring is critical, as it must be durable enough to withstand the pressures, temperatures, and wear of the system. The size and design of the ring should also match the components it is being used with. Additionally, choosing a reliable supplier that offers high-quality, customizable setting rings is important to ensure the longevity and efficiency of your systems.

Conclusion

In conclusion, Setting Rings are crucial components in ensuring the optimal performance of Hydraulic and Pneumatic Systems. These rings help maintain alignment, control pressure, and prevent leaks, ensuring the efficient operation of machinery in various industries. Whether in construction, automotive manufacturing, or aerospace, setting rings are indispensable for achieving long-lasting, reliable performance. By understanding their role and selecting the right setting ring for your application, you can significantly enhance the efficiency and lifespan of your hydraulic and pneumatic systems.

Integrating high-quality Setting Rings into your machinery ensures optimal fluid flow, pressure control, and alignment, which are essential for operational success. Whether you are working in the Automotive, Aerospace, or Manufacturing Industries, setting rings should be a critical part of your system’s design and maintenance plan.